Retailers implementing RFID will reap business benefits, from improving merchandising and store processes to increasing customer engagement. It all starts with improved inventory accuracy.

Retailers use RFID to track merchandise throughout the supply chain, from warehouse shelves to the sales floor. It helps them serve BOPIS shoppers and reduce stockouts.

Retailers use RFID to track merchandise throughout the supply chain, from warehouse shelves to the sales floor. It helps them serve BOPIS shoppers and reduce stockouts.

Inventory Accuracy

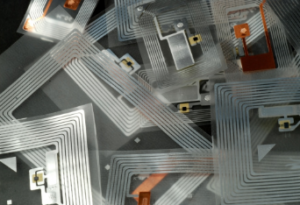

RFID has numerous advantages in retail inventory management compared to traditional barcode scanning. For instance, RFID tags can be batched and scanned—everything in one column or row of inventory can be read at once—making cycle counting much faster and more accurate. It is especially helpful when working with high-density lists or large quantities of products, such as apparel. RFID also makes restocking quicker, more precise and less labour-intensive for employees and customers. For more RFID retail buy. Click here.

Moreover, RFID can provide more data than a barcode scan, including item location, description and attributes, and even product images and video. It can help retailers reduce out-of-stock situations and enable new customer experiences, such as buying online, pickup in-store (BOPIS).

Improved inventory accuracy is perhaps the most significant benefit of a retailer’s investment in RFID. It is because traditional inventory count methods require intensive labour and are often inaccurate. Moreover, they are impractical for some products and retail environments.

On the other hand, RFID provides real-time inventory information to retail staff and customers through its tag technology. For example, when a retailer receives a case of new apparel from a wholesaler, the RFID tags on those items are automatically updated with accurate inventory counts. It eliminates the need to scan each garment manually and ensures that the correct stock is moved from the warehouse to the sales floor.

Then, when a customer comes in to purchase those new jeans, the store can offer them on-the-spot pickup or delivery. This way, the retailer can fulfil omnichannel orders more quickly and cost-effectively.

Moreover, the accurate inventory information from RFID can streamline and possibly eliminate the checkout process. A retail shopper could walk through an RFID-enabled checkout gate with their bag or cart already loaded with their preferred payment method and pre-loaded customer loyalty account for more RFID retail buy. Click here.

Additionally, by tracking product movements within a store, retailers can identify hotspots—end caps, pinch points and different employee and product paths—and adjust their merchandise displays accordingly. In short, a well-implemented RFID solution can transform each store into its distribution centre, which is excellent news for retailers seeking to maximize omnichannel revenue.

Inventory Reliability

The ability to see and control inventory accurately is crucial for retail managers to drive sales. It also helps reduce operational costs, improve customer service and support omnichannel operations. Item-level RFID delivers on this promise. Using item-level data, retail executives can understand how inventory accuracy deteriorates and proactively make changes to reduce errors. It is possible because the data can be simulated and the results analyzed in advance.

A recent study found that item-level RFID can improve inventory accuracy by 65%-75%. It is achieved through fewer complete inventory counts, more frequent partial inventories and improved on-floor product availability.

By eliminating manual processes such as individual package scanning and blind receipts and reducing cycle count time, retailers can drastically reduce inventory-related labour hours. It frees employees to focus on more value-added tasks, reducing the opportunity for human error.

The same level of reliability applies to replenishing the store floor, allowing retailers to get the right products to the shelf in real-time and avoid costly stockouts. In addition, merchandising teams can use RFID to track the effectiveness of their displays and make changes accordingly.

RFID’s granular, item-level data can also deliver powerful insights that help reset store economics and drive sales. For example, it’s common to find that specific sizes of items are selling better in certain stores or that customers prefer to buy a different style or colour. This insight can increase full-price sell-through, reduce markdowns and improve staff productivity.